OUR PRODUCTS

We supply the metals and minerals used to help the world grow

The metals and minerals we provide are used in everyday life, and for the transition to low-carbon energy – iron ore for the steel in electricity infrastructure, copper for renewable technology, aluminium for lightweight cars, and lithium for batteries.

We continue to build the sustainability of our own mining and processing practices, while also helping our customers do the same.

We’re focused on

- Investing in materials necessary for the energy transition, and helping customers develop more secure and sustainable supply

- Providing low-carbon products, like our Canadian aluminium, and progressing ELYSISTM zero-carbon smelting

- Helping customers to decarbonise their processes through R&D

IRON ORE

Iron ore is the primary raw material used to make steel. Steel is strong, long-lasting and cost-efficient – making it perfect for everything from washing machines to cars, bridges and skyscrapers. According to the World Steel Association, steel is the most commonly used alloy in the world. Global steel consumption is forecast to grow by 1%-2% per annum over the next decade.

The first known steel application dates as far back as 11th century BC, in Cyprus where archaeologists found material suggesting that steel knives were already being made. Four centuries later, the Greek historian Herodotus referred to steel-inlaid bowls and, in the 3rd century BC, South Indian craftsmen were known to produce steel by smelting wrought iron with charcoal, using clay containers. The Bessemer process to manufacture steel was developed by British inventor Henry Bessemer in the mid-1850s. In the middle of the twentieth century, the Bessemer process was refined into the Basic Oxygen Process that is still used today in blast furnaces. Today, new technologies have great potential to improve how we engage with our markets.

Aluminium

Lightweight and infinitely recyclable, aluminum is found in everything from jet engines to electric vehicles to mobile phones. It is the most abundant metal in the Earth’s crust, and one of the world’s fastest growing major metals. But we are only scratching the surface of the opportunities for aluminum to be a part of our everyday lives. According to the Aluminum Stewardship Initiative (ASI), for every 10% reduction in the weight of a vehicle, fuel economy increases by about 7%. Over its lifetime, every kilogram of aluminum that replaces heavier materials in a car or light truck can save a net 20 kilograms of carbon dioxide emissions.

Aluminum is made from bauxite, or aluminum ore. Bauxite is the basic raw material that is refined into alumina, which in turn is sent to smelters for processing into aluminum. First discovered near Les Beaux in the South of France in 1821, bauxite was initially called “beauxite”. In 1886, Charles Martin Hall and Paul Héroult independently developed a process for making aluminum from alumina. And in 1887, Austrian scientist Karl Josef Bayer patented his self-titled process for extracting alumina from bauxite. Today, the Bayer process and the Hall-Héroult process are still combined to process bauxite ore into alumina, and then convert it into aluminum.

COPPER

From the days of antiquity, copper has been used for its many benefits: tough but malleable, corrosion-

resistant and recyclable, and an excellent conductor of heat and transmitter of electricity. Copper plays a critical role in the clean energy transition

Copper powers our everyday lives.

Copper has many important jobs. It’s found in everything from pots and pans, to the water pipes in our homes, and the radiators in our cars. And it plays an essential role in computers, smartphones, electronics, appliances, and construction. Used as a tiny antenna in many hearing aids, Copper helps people hear for the first time. And bonus: it has antimicrobial properties, meaning it helps keep bacteria away.

Copper is the best non-precious conductor of heat and electricity on the planet. So it’s found in everything from the electrical wiring in your house to renewable power sources like wind turbines. And because it can help things work more efficiently, it’s going to play an important part in a more sustainable future.

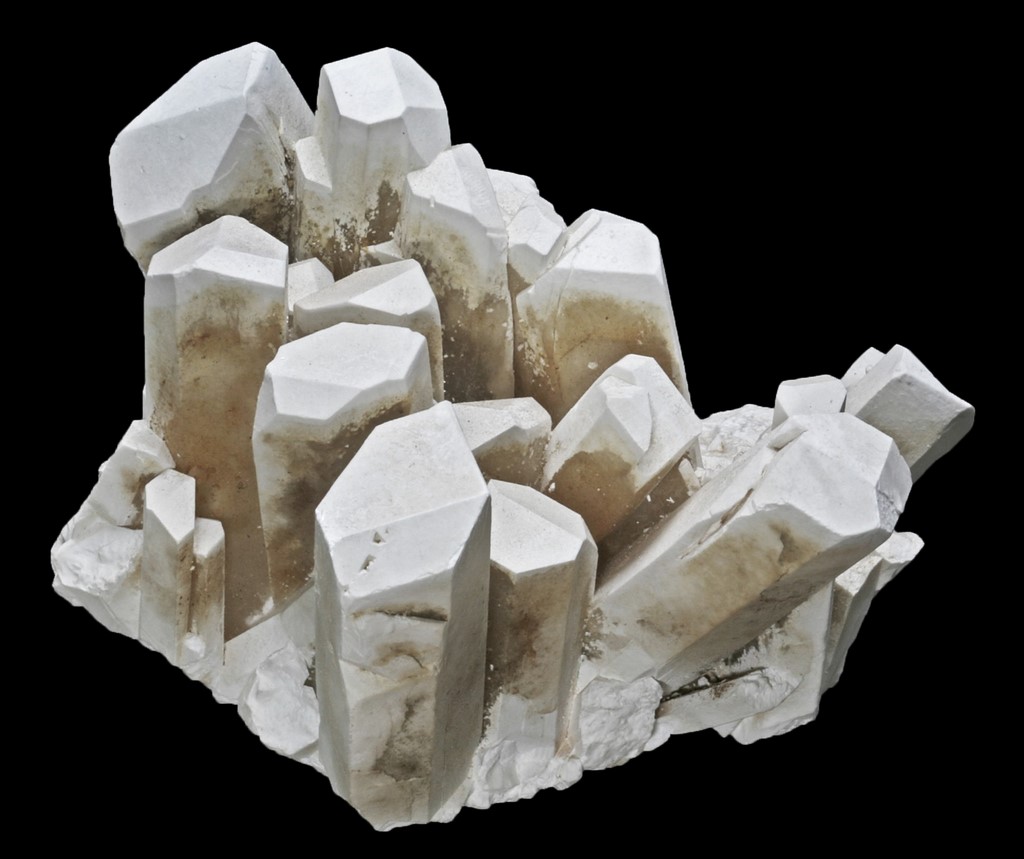

BORATES

Deposited millions of years ago, borates are crystallized salts that contain boron. Boron is a mineral essential to plant growth, so it is used in fertilizers, but it is also used in high tech applications, such as the heat-resistant glass for smartphones, materials for renewable energy – like wind, solar and EV batteries, wood protection and fiberglass insulation.

Commercially viable quantities of this rare and versatile mineral have been found in very few places in the world. One is in California’s Mojave Desert, where we started mining more than 150 years ago first in Death Valley and then moving, in 1927, to Boron.

A touch of glass – Heat-resistant glass takes center stage in the world of smartphones, tablets and televisions. Borates help make this glass possible. A typical smartphone or tablet touchscreen contains 2 types of glass: cover glass, the borates-bearing, scratch-resistant surface that you touch; and substrate glass, enabling the technology for the display itself.

LITHIUM

Lithium is an essential ingredient in lithium-ion batteries for hybrid and electric cars, as well as rechargeable power for laptops, phones and other devices. It is the lightest of all metals, making it well suited for use in everything from pacemakers to jets.

Lithium does not occur on its own in nature but is found combined with other minerals. At our Rincon Lithium Project in Argentina, we have the capability to extract and produce battery-grade lithium carbonate from raw brine. At our Jadar project, we discovered lithium in a new mineral in the Jadar Valley in Serbia, now known as jadarite.

Lithium is part of our portfolio of materials essential to a low-carbon future. Lithium is a key element needed for low-carbon technologies including the electrification of transport, large-scale batteries and energy storage. Double digit growth in lithium demand is forecast over the next decade.

SCANDIUM

Considered a critical mineral by several countries scandium is a rare, versatile and useful metal. Scandium is the most effective known microalloying element that can strengthen aluminum, while also offering improved flexibility, resistance to heat and corrosion, and lighter weight.

For this reason, military and civilian aircraft have used aluminum-scandium alloys for decades to improve fuel economy, maneuverability and range. These alloys are used in the aerospace, energy (for solid oxide fuel cells), automotive, and 3D printing industries.

They’re also used in sporting equipment, such as baseball bats, lacrosse sticks and bicycle frames, because of their lightweight properties – bicycle manufacturers estimate that scandium reduces the weight of their aluminum frames by up to 15%. Scandium can also be found in electronic ceramics, lasers, LED lighting, glass and many more applications where its unique properties make it a valuable addition.

FERROUS METALS

Diverse products, consistent quality

Ferrous metals are any metal that contains iron. Because of their strength, you can find ferrous metals in everyday items from skyscrapers to cars. They’re also extremely durable, which is why ferrous metals are used in bridges, shipping containers and smaller manufacturing components that are subject to wear and tear.

With a steady supply of high purity ilmenite ore, we supply global markets with a diverse mix of iron and steel products including metal powders, steel billets and high purity pig iron (HPPI). Founded in 1967, our Critical Minerals and Technology Centre continues to be a stronghold of innovation. We have state-of-the- art equipment and highly specialized instruments, such as an inductively coupled plasma spectrometer, x- ray spectrometer, atomic absorption unit, image analyzer and scanning electron microscope.

TITANIUM

Titanium is a vital building block for renewable energy

When metal has to perform in extremely cold environments, like outer space; in extremely hot ones, like an airplane engine; or extremely corrosive ones, like seawater, titanium is a strong choice – because of its high strength, light weight and resistance to corrosion. It’s now being used to make highly efficient solar panels, underwater heating pipes, and renewable energy infrastructure. And because it’s lightweight, it can also help reduce fuel consumption, letting planes and cars go farther with less impact on our environment.

Titanium dioxide is a very white, opaque compound that absorbs ultraviolet rays and reflects 96% of light, so it’s been a primary ingredient in products like sunscreen, toothpaste, paint and cosmetics for over a century. These same properties are lending it to new applications that reduce carbon emissions – like paint used on buildings to reflect heat and reduce air conditioning energy consumption, and battery and solar technology.

PALLADIUM

As overall mine production of palladium reached 210,000 kilograms in 2022, Russia was the top producer followed by South Africa, Canada, the U.S., and Zimbabwe. Russia’s company Norilsk Nickel ranks first among the largest palladium producers globally, accounting for 39% of the world’s production. Palladium is found in the rare minerals cooperite and polarite. Many more Pd minerals are known, but all of them are very rare.

Palladium is also produced in nuclear fission reactors and can be extracted from spent nuclear fuel (see synthesis of precious metals), though this source for palladium is not used. None of the existing nuclear reprocessing facilities are equipped to extract palladium from the high-level radioactive waste.

A complication for the recovery of palladium in spent fuel is the presence of 107 Pd, a slightly radioactive long-lived fission product. Depending on end use, the radioactivity contributed by the 107 Pd might make the recovered palladium unusable without a costly step of isotope separation.

RHODIUM

Rhodium is found in platinum or nickel ores with the other members of the platinum group metals. It was discovered in 1803 by William Hyde Wollaston in one such ore, and named for the rose color of one of its chlorine compounds. Rhodium detectors are used in nuclear reactors to measure the neutron flux level. Other uses of rhodium include asymmetric hydrogenation used to form drug precursors and the processes for the production of acetic acid.

The element’s major use (consuming about 80% of world rhodium production) is as one of the catalysts in the three-way catalytic converters in automobiles. Because rhodium metal is inert against corrosion and most aggressive chemicals, and because of its rarity, rhodium is usually alloyed with platinum or palladium and applied in high-temperature and corrosion-resistive coatings. White gold is often plated with a thin rhodium layer to improve its appearance, while sterling silver is often rhodium-plated to resist tarnishing. Rhodium is sometimes used to cure silicones: a two-part silicone in which one part containing a silicon hydride and the other containing a vinyl-terminated silicone are mixed; one of these liquids contains a rhodium complex.